Viscoelastic Liquid Drop Generator

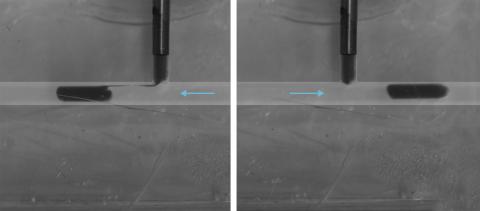

A patented method of creating discrete droplets of a desired size from viscoelastic materials, eliminating waste caused by the beads-on-string effect, which is a common problem when dispensing viscoelastic material.

Download the Non-Confidential Brief

Commercial Applications:

- 3D printing of polymer solutions/melts

- Ink/Bioink-jet printing/Drop-on-Demand

- Dispensing of protein solutions/biofluids

- Printable electronic circuits and components

- Continuous encapsulation of viscoelastic fluids

- Viscous liquid packaging equipment

- Electronics – surface mount technologies

- Selective adhesive processes

- Custom gasket sealing applications

Innovation Benefits:

- Handles a wide range of viscoelastic materials

- Eliminates the beads-on-string effect

- Produces precise uniform droplets

- Customizable configurations

- Reduces waste of costly material

- Fast and efficient production method

Technology Overview

In almost every situation involving fluid handling, from the lab bench to the factory floor, viscoelastic fluids are present. Typically, dispensing viscoelastic materials is plagued by long filament and multiple daughter drop formation seen in the beads-on-string effect. Given the wide ranges of viscoelasticity different fluids may possess, current technology struggles to precisely dispense these difficult fluids. This UNH innovation successfully eliminates the detrimental beads-on-string effect in a laboratory setting. Its customizable design can be adapted to a microscale or macroscale for a wide range of droplet sizes and production speeds. It can also be refined for a specific range of viscoelasticity for a given material. Dispensing can be done using an immiscible carrying fluid or gas. The device and methodology are ripe for utilization, and the process can be scaled up to address much larger manufacturing needs.

Lead Innovators, Brian Zukas, Ph.D. & Nivedita Gupta, Ph.D.

Dr. Brian Zukas received his Ph.D. in chemical engineering from the University of New Hampshire in 2018. He also has a B.S. and M.S. in chemical engineering from UNH. He has expertise in viscoelastic fluid flows, encapsulation, and microfluidics.

Nivedita Gupta, Ph.D. is a professor of chemical engineering at UNH. Gupta received her Ph.D. in chemical engineering from Penn State University in 1999. Her research interests are in the areas of interfacial flows, Marangoni flows, computational fluid dynamics, and microfluidics.

For more information, please fill out the inquiry form below

Licensing Inquiry Form

Or contact us directly:

Maithili Shroff, Licensing Manager for Engineering & Physical Sciences

maithili.shroff@unh.edu | 603.862.4054

Archive

-

2021

- September 2021

Betty and Barney Hill Collection

- MARCH 2021

Innovations in Aqueous Electrochemical Energy Storage Devices

-

2020

- MARCH 2020Viscoelastic Liquid Drop Generator

- February 2020IOL INTACT® Protocol Testing Software

- JANUARY 2020SIMAP®

-

2019

- AUGUST 2019

- JULY 2019

- JUNE 2019

- APRIL 2019

- MARCH 2019

- JANUARY 2019

-

2018

- DECEMBER 2018

- OCTOBER 2018

- SEPTEMBER 2018

- JULY 2018

- JUNE 2018