Every month, we highlight an outstanding example of UNH intellectual property with excellent commercial potential. Contact unh.innovation@unh.edu for more information about any of UNH's innovations.

Novel Chiral Cellular Structures with Tailorable Auxetic Effects Under Large Deformation

The June Innovation of the Month is Professor Yaning Li's novel process for producing highly deformable chiral structures that have different core cell configurations.

Download the Innovation Brief

Key Features

- Geometrically shaped core cells

- Ribbed sections extending from the core cell

Key Benefits

- Enhanced stretch properties (thicker when stretched)

- Enhanced compression properties

- Increased stiffness

- Customizable stress-strain properties

Applications

- Biomedical scaffolds

- Drug-Delivery Bandages

- Energy Absorption Foams

- Impact & Tear Resistant Materials

Stage of Development

Laboratory production demonstrated; Commercial development needed

Intellectual Property Status

Patent application has been filed

Overview of the Innovation

Auxetic materials are deformable composites that have a negative Poisson’s ratio. These materials behave differently than common materials in that they actually expand when stretched. This new process can be used to selectively modify the mechanical properties of auxetic chiral cellular composites by changing the shape of the cellular core to achieve varying levels of structural stiffness and Poisson’s ratio and adding desired levels of mechanical deformation when tension and compression loading (either through direct mechanical loading or indirect loading due to temperature change, swelling etc.) are applied.

Development Process

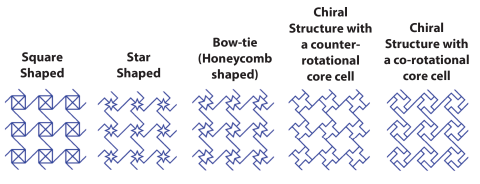

The shape of existing chiral cellular structures was changed by altering the re-entrant angle of the cellular core. Square, star, and bow-tie (honeycomb), and chiral shaped core cells were evaluated. Standard chiral structures with counter-rotational and co-rotational core cells were also evaluated:

Stress-strain curves under tension and compression conditions were analyzed to document the mechanical behavior of the modified chiral structures.

Competitive Advantage

A multi-step sequence was developed to create enhanced microstructures that can withstand large deformation forces without buckling and collapsing. The process retains the desired auxetic characteristic of having a negative Poisson’s ratio and adds a structural enhancement by rotating the core cells which allows the structure to withstand high tension and compression deformation, and provide a unique cell opening mechanism. Traditional rubber materials can easily undergo shape deformation changes, but are relatively incompressible. Auxetic materials will maintain shape and are easy to change the volume. Similarly, metallic materials used for bone implants offer stiffness, but can also cause negative effects such as stressshielding and surrounding area bone fractures. Use of auxetic materials allows for the design of mesh constructions that better matches bone structure and reduces stress shielding.

Market Opportunity

Commercial interest in auxetic materials is growing rapidly in the biomedical device, aerospace, and transportation sectors, mechanical metamaterials, and smart composite materials. In the biomedical space, applications include medical scaffolds and drug delivery bandages. In the aerospace sector, there has been interested in the development of “smart” textile fabrics that harness solar energy. The transportation sector has many application areas that include vibration damping materials and composites that deform to reduce damage. The development of “smart textile” materials in the high performance apparel category is also rising with applications such as the Under Armor Micro G Drive “Volt” sports shoe.

Lead Innovator: Yaning Li, Ph.D.

Prof. Li’s research interests are in mechanics of materials, bio-inspired engineering and additive manufacturing (3D printing). Her research focuses on solid and structure mechanics, fracture mechanics, and mechanical behaviors of metals, polymers and composites across all length scales. In particular, she is interested in unveiling physical principles in biological systems and therefore developing novel micro-structured composite materials.

Archive

-

2021

- September 2021

Betty and Barney Hill Collection

- MARCH 2021

Innovations in Aqueous Electrochemical Energy Storage Devices

-

2020

- MARCH 2020Viscoelastic Liquid Drop Generator

- February 2020IOL INTACT® Protocol Testing Software

- JANUARY 2020SIMAP®

-

2019

- AUGUST 2019

- JULY 2019

- JUNE 2019

- APRIL 2019

- MARCH 2019

- JANUARY 2019

-

2018

- DECEMBER 2018

- OCTOBER 2018

- SEPTEMBER 2018

- JULY 2018

- JUNE 2018